Multi Alignment

- In the past, the only way to print solder on ceramic interposer board was to provide solder using a dispenser or to print on interposer board one by one. The reason is because misalignment between the mask and the board occurs due to the variation of the interposer board external dimension when trying to print on multiple interposer boards as a batch placed on JEDEC trays. Minami developed “Multi Alignment” feature, a multiple substrates transporting and positioning mechanism, and solved the problem.

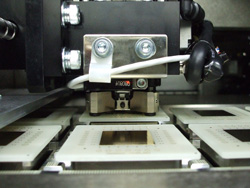

- Work piece positioning manipulator

A manipulator located above the transport conveyor and underneath the screen mask, operates as an independent unit. The manipulator (on the work side) has a suction function, which picks up the work from the printing table and corrects the X, Y and θ position. After that, the works are fixed by vacuum and printed as a batch (multiple substrates simultaneously) in high accuracy.

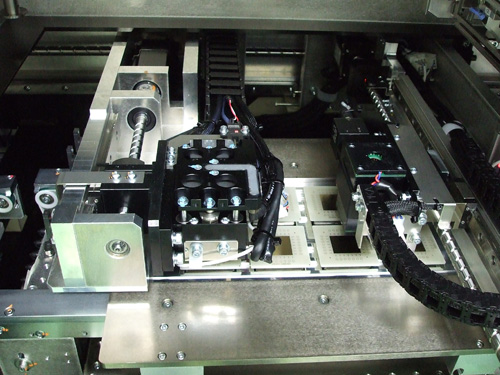

- Multiple substrates transporting and positioning mechanism

JEDEC tray or the customer designated tray can be used as is for the number of substrates desired to be printed simultaneously. As a result, transportation, vision correction, positioning and printing can be carried out efficiently.

- Transition of operation by Multi Alignment mechanism

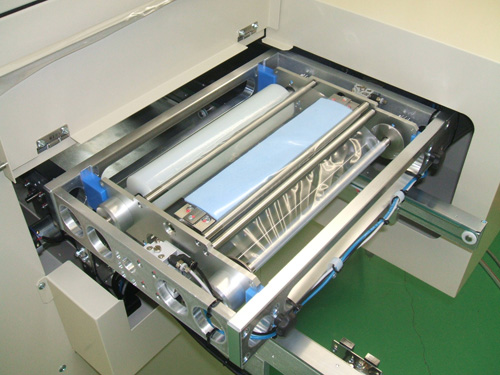

- Cartridge type detachable cleaning unit

By introduction of a cartridge type for the cleaning unit, attaching and detaching the cartridge is substantially simplified, and also switching between the cotton type and the adhesive type can be made easily.

- Please refer to the animation of the MK-888SV(Multi Alignment) for the details.

Copyright© 2013 MINAMI Co.,Ltd. All rights reserved.