MK-BP5000

High-spec Solder Ball Placer

Features

- New Transfer system

Quality stabilization and high productivity by the Dual Table Transfer System

20 sec/pcs *At the PCB Type Dual Optimal conditions

Each process at the PCB type Dual are correspond one stencil (flux stencil / ball stencil 1 pcs on each)

- Unique Technology (Rotary Squeegee/Cyclone head)

- Ball Size : φ60um ~φ600um

- Automatic solder ball supply / Automatic flux suppl

| Adaptive Materials | |

|---|---|

| Stencil Size (X)x(Y) |

1) 750mm x 750mm 2) 736mm x 736mm |

| PCB Size (X) x (Y) |

Dual: 200mm x 60mm - 250mm x 250mm Single: 1) 50mm x 60mm - 360mm x 370 mm 2) 50mm x 60mm - 360mm x 170mm, φ300mm Thickness: 0.1mm - 2.5 mm |

| Performance | |

| Productivity | PCB : Type Dual 20secs / 1 sheet *Optimal conditions |

| Print positioning repeatability accuracy | ±0.01mm |

| Specification | |

| Power supply utility | 3 phase 200V - 240V Frequency 50/60Hz |

| Used air utility | 0.49MPa : 800NL/min |

| Direction of setting work | 1) Left → Right 2) Right → Left |

| Distribution line | From floor 900±20mm |

| UI language | Japanese/English/Chinese/Korean |

| Machine Weight | Approx. 2700kg |

| Printing Direction | Front ↔ Rear / Left ↔ Right |

| Vision FOV | 13.5mm x 10.8mm |

| Software operating system | Windows 10 |

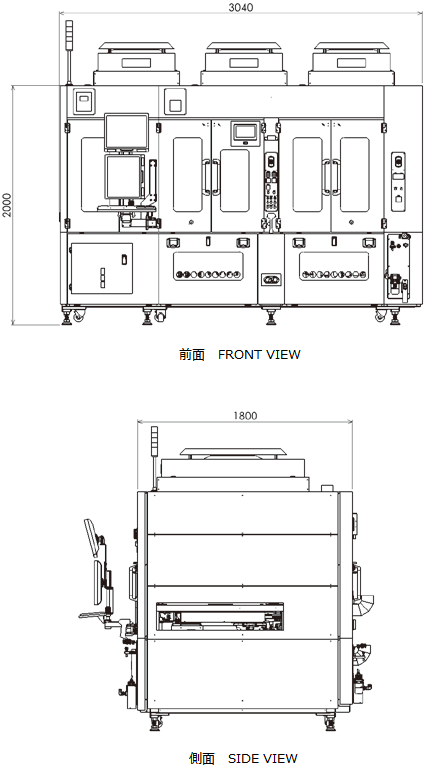

| Lay-out | Dual type : (W)3040mm x (D)1800mm x (H)2000mm Except tower / monitor / FFU |

| Option | |

| Loader and Unloader system Wafer transfer Robot PCB Cleaner Warpage Correction Unit Fan filter unit ・ Ionizer |

|

External View

MINAMI Co., Ltd. headquater ;38-32, 5-chome, Minami-cho, Fuchu-shi, Tokyo, Japan

Copyright© 2013 MINAMI Co.,Ltd. All rights reserved.