MK-BP5000IR

Ball Inspection & Rework MK-BP5000IR

Features

- New Transfer system

Dual Table Transfer System provides stable quality and high productivity. - Solder ball Inspection System

High speed & accuracy inspection - Solder Ball Rework System

Rework Ball Size: φ45µm~φ600µm

Rework missing ball, double ball, misalignment - Repeatability accuracy:±10µm

| Materials | |

|---|---|

| Work Size |

Dual:Max.(X)305mm×(Y)250mm Thickness : 0.08~2.5mm |

| Work Warpage | Max. 10mm |

| Ball Size | Min. φ45µm ~ Max.φ600µm |

| Performances | |

| Rework Productivity | 8sec / 2ball (2 Head) For missing balls |

| Repeatability | ±10µm |

| Specifications | |

| Power supply utility | 3Φ 200V~240V Frequency 50/60Hz |

| Used air utility | 0.5MPa, 900NL/min |

| Direction of setting work | Standard : Left → Right Option : Right → Left |

| Distribution line | From floor 950±10mm |

| UI language | Japanese/English/Chinese/Korean |

| Machine Weight | Approx. 2,400kg |

| Inspection camera | 67M Pixel(CMOS), 5.68um/Pixel(×0.44,Telecentric) |

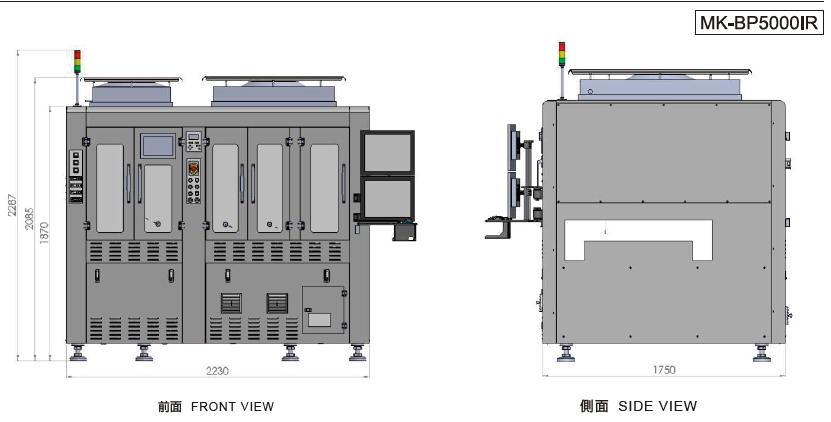

| Lay-out | 2,230mm(W) 1,750mm(D)2,085mm(H) except tower/monitor |

| Option | |

| PCB Loader by Cassettes Ionizer UPS |

|

External View

MINAMI Co., Ltd. headquater ;38-32, 5-chome, Minami-cho, Fuchu-shi, Tokyo, Japan

Copyright© 2013 MINAMI Co.,Ltd. All rights reserved.